After some test driving, the car seemed operating quite well. It was time to take it to rolling road dyno to make final adjustments and find out the power figures of the engine. Some plastic hoses in the engine compartment had to be replaced before that, because those did not withstand heat. There was some problems with the belt drive of the alternator, too.

As deduced from test driving, there was very rich mixture with the '55' idle jets. '50's were also too large while '40's being too small. The homemade lambda meter seemed to be practical for measuring the air/fuel ratio.

Later, it was found that the '50' idle jets I had used were not actually that size... those items were drilled to 0.58mm thus causing the rich mixture. Originally, those were extracted from old rally carbs... you get what you pay for. The '50' was the correct idle jet size for the engine. The idle screws were adjusted using exhaust gas analyzer.

According to the Finnish regulations about street cars, a passenger car can have maximum 20% more power than the most powerful model made with the same chassis. Using the 1049cc 127 sport (70 bhp) as comparison, I can legally get 84 bhp from my engine. Since 105 bhp were achieved at the first dyno run, the boost pressure had to be lowered slightly. After that, I got an 'official' dyno sheet that can be used when the car is being inspected. Of course, I can have on track any boost I like.

Because the engine is almost stock, the maximum rev rate at the dyno were set to 7000RPM. The engine seems to need breakerless ignition system because there was huge problems with bouncing breaker points above 6000RPM. Otherwise, the engine performed quite well and there was no heat problems despite of having quite low power cooling fan during the dyno runs. The exhaust manifold was very hot causing some complication when adjusting the wastegate.

After the dyno runs, it was time to fix the alternator problem. The belt was slipping because it was barely touching the alternator pulley. Consequently, the belt was in very bad condition although the car had only done 100km. Crankshaft, alternator and water pump were equipped with cogged belt pulleys made from Lancia balance shaft pulleys. A Toyota timing belt was found from Gates catalog, it seemed to have suitable length and tooth profile. There was some struggle to make a workable tensioner assembly for the belt, but now it operates quite well.

Alignment of the water pump is not very accurate and this causes the alternator pulley to slip a little sometimes. Maybe the pump will be equipped with electrical motor in the future.

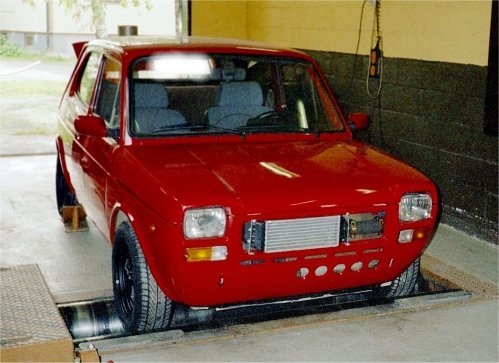

I added one more silencer and the car become significantly quieter and its sound became low-pitched. Also, the car was equipped with its original bumpers (to have cool sleeper-look :-). The original wheels were replaced with 185/55/14 items fitted on Fiat 132 rims.

After that, the car became ready for to be inspected for road use. Finally, after six-year labor, the car got it's license plates.

While spending a few days on road, some modifications worth of doing come to my mind. Of course, the ignition system must be replaced with breakerless item, and an expansion tank will be added to the coolant system. Probably I will use Regata 100S tank.

The copper headgasket seems to leak a little from the cylinders to the water galleries. I have heard that some special gasket sealant should be used with these gaskets, but I don't have accurate information on that... is someone knows better, please let me know.

Also, the engine is quite difficult to start particularly when it is hot. I don't know if this is a common problem with blow-through carbureted turbo engines... I think that fuel vaporizes in the carbs and gets trapped in the intake passages. This excess fuel is drawn into the engine during starting. This is not a major problem, because the engine starts when cranked a few seconds with wide open throttle. However, it would be nice to get it start right away after turning the key.

At least, the accelerator pump jets are way too large (35) and those will be replaced with smaller units. Those provide too much fuel when the throttle is depressed before starting.

Next part