(...continued from page 1)

Suspension parts & related stuff

Every component that fits into the phosphoric acid bath was cleaned using that method. This is one of the most effective and effortless ways to remove all the rust from loose parts. Big parts needed to be wire-brushed and soaked with acid using a paint brush.

A good method for working with some persistent rust spots is to soak some paper towel with the acid and arrange them over the spots. The paper towel prevents the acid from drying out too early.

Parts free from rust - prior and after painting.

My son has helped with the project significantly.

The rear axle was painted with zinc primer, paint and finally coated with a (rubber/resin based) corrosion preventive compound.

All doors were in poor condition from their bottom. The easiest way was to cut the door panel from the middle and renew everything from there to the bottom. I think this is also the best way to do it, from quality point of view. Zinc coated steel was again used.

All the rust was removed from roof with acid, because the material thickness was thin on many places, because of corrosion. After that, the rust-free surface was coated with zinc-based paint.

The rear end of the car and windshield sides needed also some attention.

After all the welding jobs, the preventive actions for painting were started.

All four outer door handles were in poor condition. Time and kilometers are started to show. Does someone know where to get new ones for a reasonable price? Handles for version 3 of the 131 are not very common.

A new, larger radiator was test-fitted...

Some suspension parts were put in place to get the chassis rolling. Many bushes were replaced with new items, made from polyurethane.

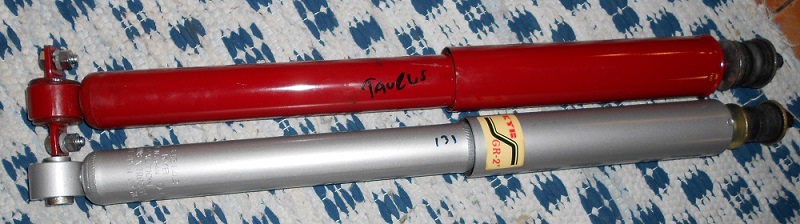

When gathering some parts for the car, I made an interesting find. The rear shock absorbers of Ford Taurus (STW, version II) were near identical to Fiat 131 items. The former one were a little bit stiffer because of the heavier vehicle.